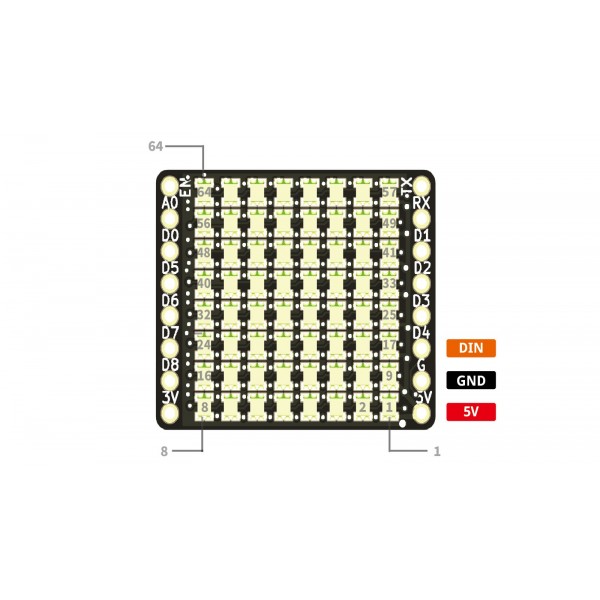

Wemos 8x8 RGB LED Shield - WS2812B-2020

- Availability: Directly available from warehouse in Eindhoven

- SKU: 005407

€5.00

Ex Tax: €4.13

Your shopping cart is empty!

A Wemos 8x8 RGB is a shield module with digital WS2812B-2020 leds.

See the following page for more information: Wiki

| General | |

| Brand | LOLIN Wemos |

| Features | Digital LED(s) |

| General physical appearance | |

| Main color | Black |

| Weight [g] | 3 |

| Dimension X [mm] | 26 |

| Dimension Y [mm] | 21 |

| Form factor | Module (general) D1 mini layout/shield |

| General electrical properties | |

| Minimum supply voltage [V DC] | 3.7 |

| Maximum supply voltage [V DC] | 5.3 |

| Minimum recommended supply current [A] | 0.9 |

| Minimum IO-pin input voltage [V] | 3.3 |

| Maximum IO-pin input voltage [V] | 5 |

| IO-pin output voltage [V] | Equal to supply voltage |

| Communication | |

| Hardware interface(s) | Digital |

| LED | |

| LED (driver) chip | WS2812B |

| LED color | RGB |

| Number of LEDs | 64 |

| Maximum current per LED [mA] | 12 (±10%) |

| Connectors | |

| Power supply connector(s) | Through hole solder pin(s) (2.54mm) |

| IO-connector(s) | Through hole solder pin(s) (2.54mm) |

| Package contents | |

| Package contents | 1x 8x8 RGB shield 2x Male pin headers 8p |

To connect a digital LED strip, we offer two options below. The first is recommended as it requires fewer components and fewer connections.

Requirements:

The following components are required to operate a product with digital LEDs:

Connecting the strip:

*There are many power supplies on the market that carry a China export ("fake" CE marking) or carry a CE marking but are not actually CE certified. We advise against using these, often cheap (Chinese), power supplies because they often do not provide a stable voltage. A stable voltage is essential to prevent damage to the LED strips and to ensure stable operation.

Requirements:

The following components are required to operate a product with digital LEDs:

The following parts are optional:

Connecting the strip:

*There are many power supplies on the market that have a China Export ("fake" CE marking) or carry a CE marking, but are in reality not CE approved. We do not recommend using these, often cheap (Chinese), power supplies because they generally do not provide a stable voltage. A stable voltage is essential to make the LEDS work stable, and to prevent damaging them.

More information:

We recommend reading the following pages for more information (especially when using multiple LED strips): Powering Neopixels and Adafruit NeoPixel Überguide.

This can have several causes. The most common causes are:

Signal voltage too low

For example, WS2812B LEDs have a signal voltage of 5V. When these are controlled with a voltage of 3.3V (as with ESP32/ESP8266/Raspberry Pi), data may not be properly received at one or more LEDs, resulting in the wrong color. This can be solved by increasing the signal voltage to 5V using a level converter.

Noise on the signal pin

The signal pin is sensitive to noise. This can be solved by connecting a 470Ω resistor in series between the microcontroller and the signal pin of the LEDs.

Voltage drop in supply voltage

Particularly with many LEDs in succession, it can happen that a part does not display the right color. This may be a sign that the supply voltage has dropped too far due to losses in the cabling. This can be solved by using extra thick power cables and connecting them between each strip.

Use a stable, CE-approved power supply with the correct voltage that can supply sufficient current. The maximum current that an LED can draw is indicated on the product page. Multiply this number by the number of LEDs to calculate the total maximum current. This maximum current is the minimum current that the power supply must be able to supply.