New

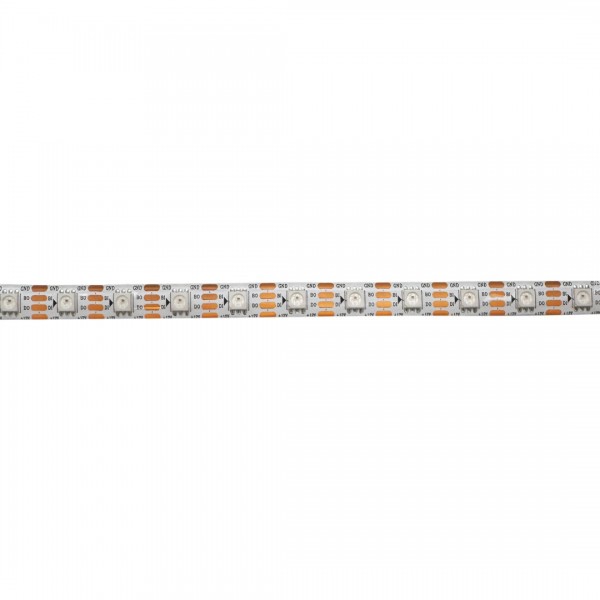

WorldSemi WS2815 Digital 5050 RGB LED Strip - IP65 - White - 60 LEDs 1m

- Availability: Directly available from warehouse in Eindhoven

- SKU: 007199

€16.00

Ex Tax: €13.22

10 or more €15.50

20 or more €15.00

50 or more €14.50

100 or more €14.00